English

Views: 0 Author: Site Editor Publish Time: 2024-08-16 Origin: Site

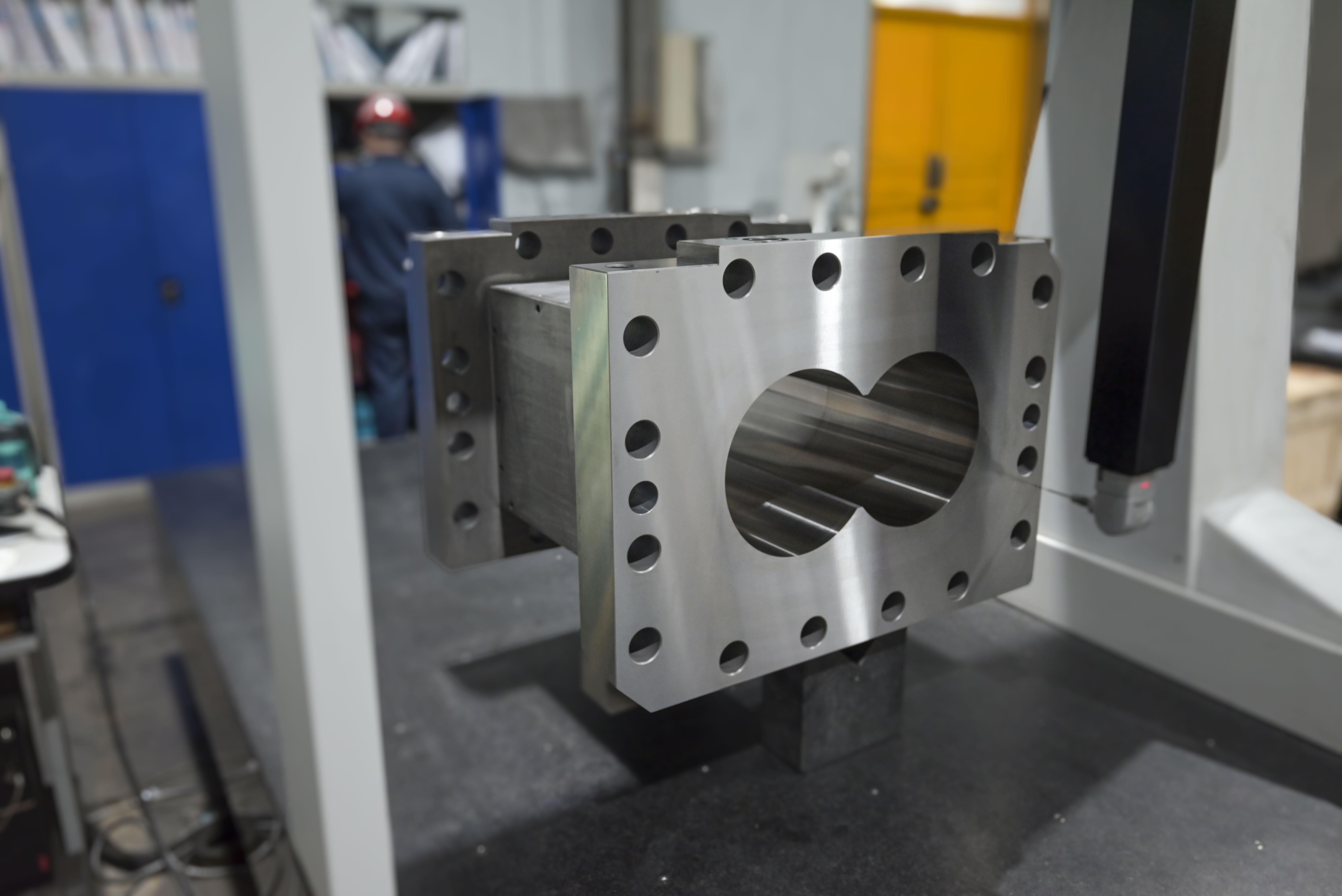

Twin screw extruders, known for their exceptional mixing, conveying, and processing capabilities, have found widespread application across numerous industries. As the core components of these machines, the performance of the barrels and gearboxes directly impacts the overall efficiency and product quality. This article explores the critical applications and advantages of twin screw extruder barrels and gearboxes in industries such as plastics, rubber, wood-plastic, films, food, feed, batteries, powder coatings, and chemicals.

In the plastics processing industry, twin screw extruders are extensively used for polymer compounding, pelletizing, and the production of modified plastics. The barrel ensures uniform heating and mixing of polymers during processing through precise temperature control and wear-resistant materials. The gearbox provides stable power transmission, supporting high-shear mixing processes to ensure consistent physical and chemical properties in the final product. This application is crucial for producing high-quality plastic pellets and composite materials.

In the mixing and processing of rubber and plastics, twin screw extruders excel as well. The barrel must withstand the high friction and temperatures generated by high-viscosity materials, while the gearbox needs to deliver sufficient torque to ensure uniform mixing and stable extrusion of rubber materials. This combination enables the extruder to produce high-performance rubber products such as seals and tires.

Wood-plastic composites are increasingly valued for their environmental benefits and excellent mechanical properties in construction and decoration. Twin screw extruders are widely used in the wood-plastic industry, where the barrel ensures the even fusion of wood fibers and plastics through precise control of mixing temperature and material proportions. The gearbox provides the necessary power to ensure smooth extrusion of high-viscosity wood-plastic mixtures, resulting in high-quality wood-plastic composite panels and profiles.

Film production requires extreme processing precision and uniformity, and twin screw extruders play a key role in this area. The barrel ensures uniform flow and forming of polymers through precise temperature control and material handling. The gearbox provides stable power support to ensure consistent film thickness and smooth surface during extrusion. These features make the extruder widely used in the production of packaging, agricultural, and industrial films.

In food and feed processing, twin screw extruders are used to produce puffed foods, pet foods, industrial feed, and more. The barrel must meet food-grade standards and provide excellent temperature control to ensure even cooking and forming of ingredients. The gearbox must remain stable during long operation, providing sufficient power to support high-volume production. This combination ensures that food and feed products maintain high consistency in shape, texture, and nutritional content.

In lithium battery production, twin screw extruders are widely used for the mixing and preparation of electrode slurries. The barrel ensures uniform dispersion of electrode materials during mixing and maintains stable physical properties through precise temperature control and wear-resistant materials. The gearbox provides robust power support for mixing and conveying high-viscosity slurries, ensuring the uniformity and quality of electrode slurries, which is fundamental for manufacturing high-performance lithium batteries.

In the production of powder coatings, twin screw extruders are used for mixing and extruding various resins, pigments, and additives. The barrel needs to provide excellent wear resistance and precise temperature control to prevent material degradation at high temperatures. The gearbox provides stable power support throughout the mixing and extrusion process, ensuring that powder coatings have excellent flow properties and color consistency. These features make the extruder a key piece of equipment for producing high-quality powder coatings.

In the chemical industry, twin screw extruders are widely used in complex processes such as mixing, reaction, and pelletizing. The barrel must handle various highly corrosive and high-viscosity chemical raw materials, requiring exceptional corrosion resistance and precise temperature control capabilities. The gearbox needs to provide continuous and stable power output to handle long-term, high-load operating conditions. This configuration enables the extruder to manage the challenging processes in chemical production, resulting in high-quality chemical products.

Twin screw extruder barrels and gearboxes play a crucial role in various industries. Whether in plastics, rubber, wood-plastic, film production, or in food, feed, battery, powder coating, and chemical industries, these core components provide stable performance and efficient power support, ensuring smooth production processes and consistent product quality. As technology continues to advance, twin screw extruders will demonstrate their indispensable value in even more fields.