English

| Availability: | |

|---|---|

| Quantity: | |

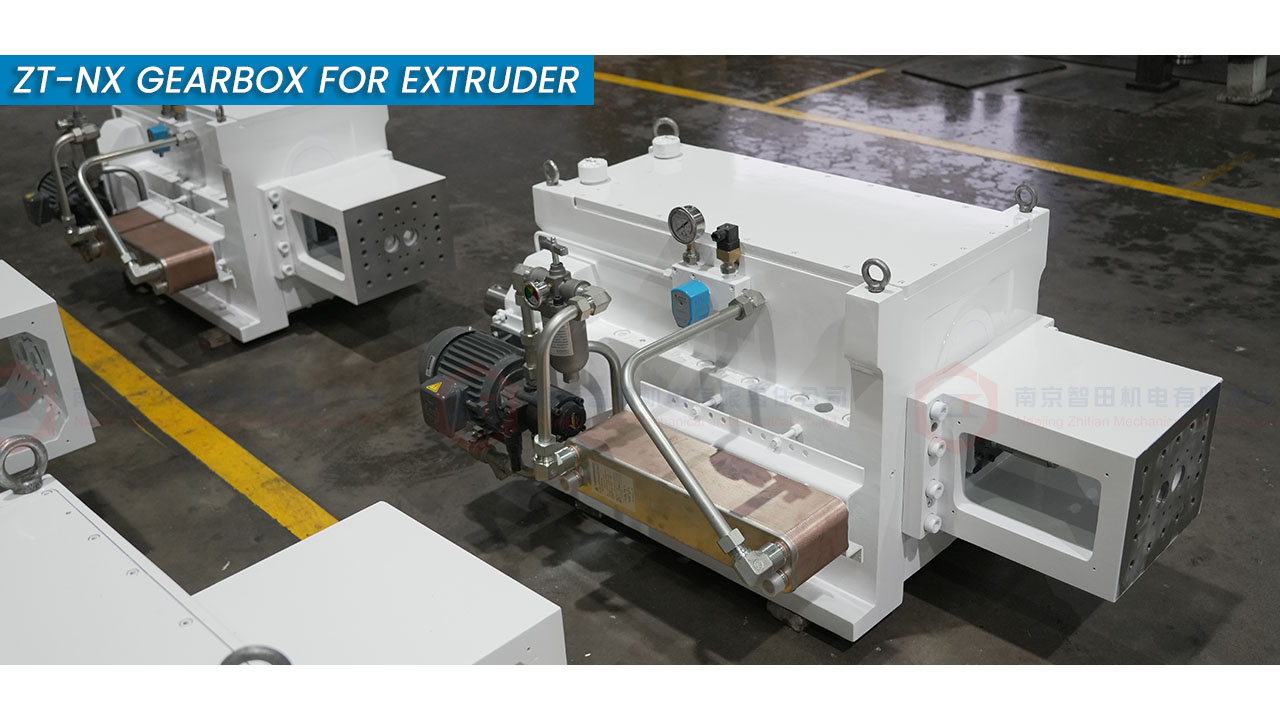

ZT-NX

zhitian

The ZT-NX twin screw extruder gearbox is a parallel-shaft, high-torque transmission unit developed for co-rotating twin screw extrusion systems. It is engineered to deliver stable torque output, precise screw synchronization, and long-term reliability in continuous production environments.

Developed by ZHITIAN based on the mature ZT-N platform, the NX series is not a complete redesign, but a systematic optimization of structure, manufacturing details, and standardization. The gearbox is widely used in plastic compounding, masterbatch production, food processing, and other extrusion applications requiring consistent torque and operational stability.

| Parameter | Description |

|---|---|

| Model Range | NX 50 / 52 / 58 / 65 / 75 / 85 / 95 |

| Shaft Arrangement | Parallel twin output shafts |

| Torque Level | High torque, application-dependent |

The gearbox housing and internal layout are refined to improve load distribution and bearing support. This reduces vibration, noise, and fatigue during long-term operation.

The ZT-NX gearbox provides high torque output while maintaining compact dimensions. Gear profiles are optimized to ensure smooth power transmission and precise screw synchronization.

Design improvements allow better manufacturing consistency and interchangeability across different sizes. This helps control cost without sacrificing performance.

Based on years of customer operation data and engineering feedback, the NX series reflects real-world performance requirements rather than theoretical optimization alone.

While maintaining the performance level of mature designs, the ZT-NX series offers improved cost efficiency, making it suitable for both equipment manufacturers and end users.

The ZT-NX twin screw extruder gearbox is suitable for:

Plastic compounding and modification

Masterbatch production

Food extrusion and processing

Chemical and functional material processing

Recycling and reprocessing extrusion lines

It supports stable operation in both standard and customized extrusion systems.

Selection depends on screw diameter, torque requirement, material characteristics, and operating speed. ZHITIAN recommends evaluating long-term load conditions rather than peak torque alone.

The NX series is based on the proven N platform but includes systematic improvements in structure, manufacturing detail, and standardization, resulting in better cost-performance without changing core performance indicators.

Yes. The NX series is designed to match most mainstream twin screw extruder interfaces, making it suitable for both new equipment and replacement projects.

It is widely used in Europe, the Americas, and Asia, supporting industrial, food-grade, and functional material extrusion applications.

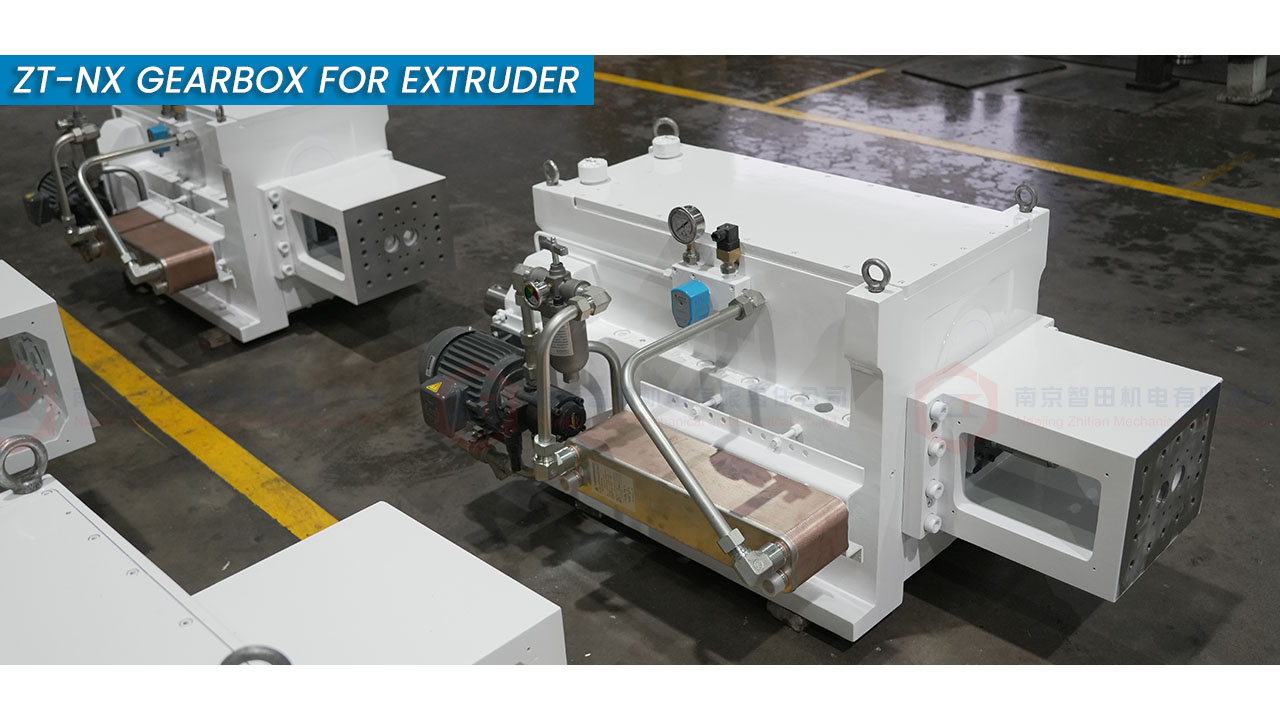

The ZT-NX twin screw extruder gearbox is a parallel-shaft, high-torque transmission unit developed for co-rotating twin screw extrusion systems. It is engineered to deliver stable torque output, precise screw synchronization, and long-term reliability in continuous production environments.

Developed by ZHITIAN based on the mature ZT-N platform, the NX series is not a complete redesign, but a systematic optimization of structure, manufacturing details, and standardization. The gearbox is widely used in plastic compounding, masterbatch production, food processing, and other extrusion applications requiring consistent torque and operational stability.

| Parameter | Description |

|---|---|

| Model Range | NX 50 / 52 / 58 / 65 / 75 / 85 / 95 |

| Shaft Arrangement | Parallel twin output shafts |

| Torque Level | High torque, application-dependent |

The gearbox housing and internal layout are refined to improve load distribution and bearing support. This reduces vibration, noise, and fatigue during long-term operation.

The ZT-NX gearbox provides high torque output while maintaining compact dimensions. Gear profiles are optimized to ensure smooth power transmission and precise screw synchronization.

Design improvements allow better manufacturing consistency and interchangeability across different sizes. This helps control cost without sacrificing performance.

Based on years of customer operation data and engineering feedback, the NX series reflects real-world performance requirements rather than theoretical optimization alone.

While maintaining the performance level of mature designs, the ZT-NX series offers improved cost efficiency, making it suitable for both equipment manufacturers and end users.

The ZT-NX twin screw extruder gearbox is suitable for:

Plastic compounding and modification

Masterbatch production

Food extrusion and processing

Chemical and functional material processing

Recycling and reprocessing extrusion lines

It supports stable operation in both standard and customized extrusion systems.

Selection depends on screw diameter, torque requirement, material characteristics, and operating speed. ZHITIAN recommends evaluating long-term load conditions rather than peak torque alone.

The NX series is based on the proven N platform but includes systematic improvements in structure, manufacturing detail, and standardization, resulting in better cost-performance without changing core performance indicators.

Yes. The NX series is designed to match most mainstream twin screw extruder interfaces, making it suitable for both new equipment and replacement projects.

It is widely used in Europe, the Americas, and Asia, supporting industrial, food-grade, and functional material extrusion applications.