English

| Availability: | |

|---|---|

| Quantity: | |

65-420

zhitian

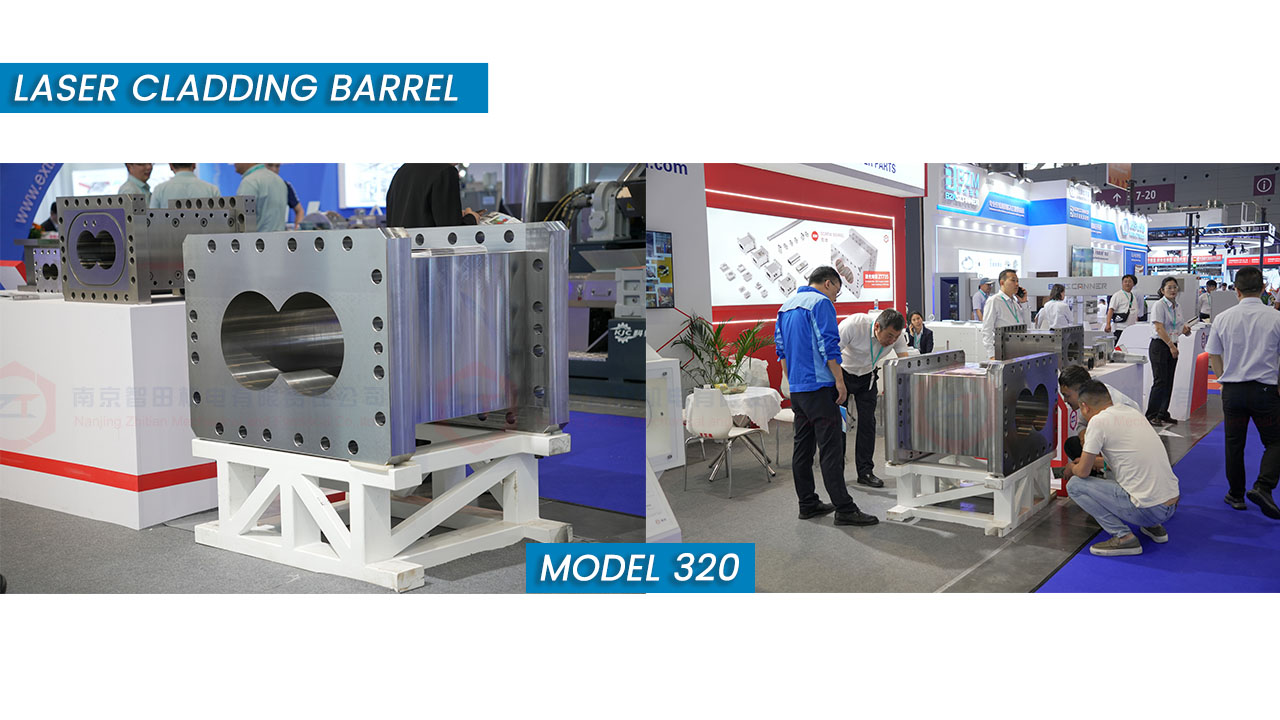

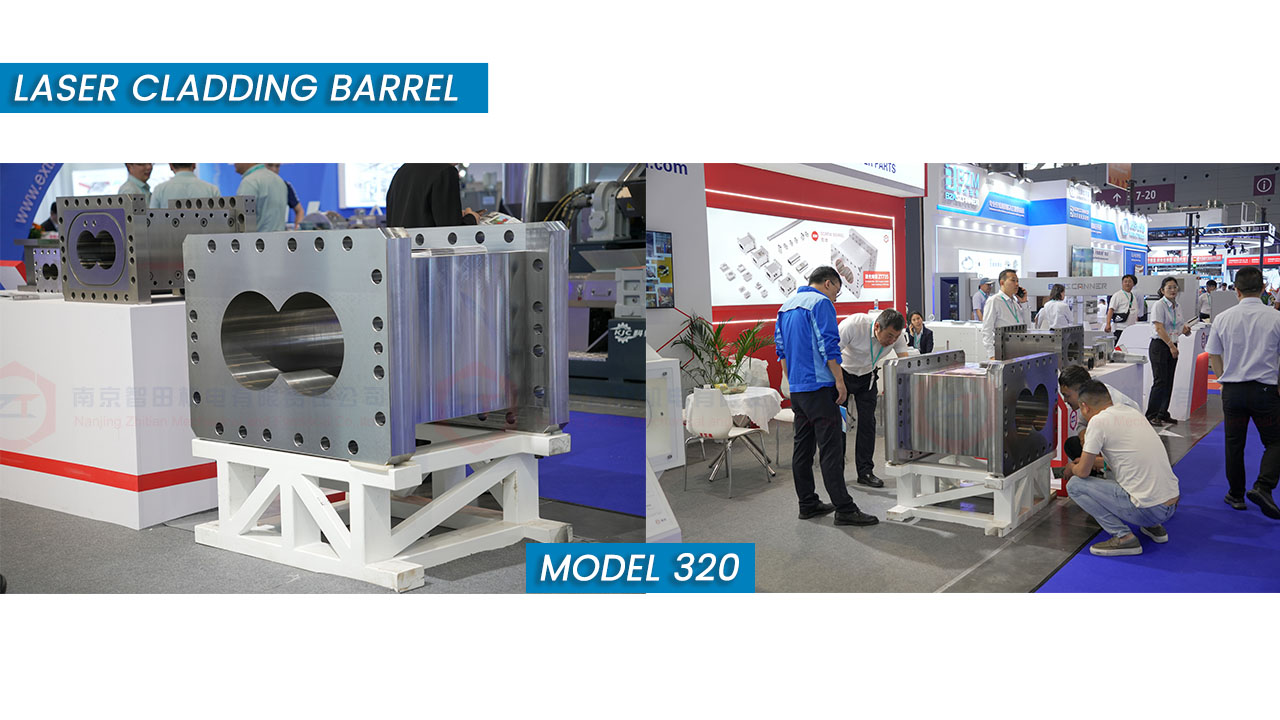

The ZHITIAN Laser Cladding Nickel-Based Tungsten Carbide Screw Barrel is engineered for twin screw extruders with diameters of 65 mm and above, delivering exceptional wear resistance, corrosion protection, and dimensional stability. Using advanced laser cladding technology, ZHITIAN provides extrusion barrels that ensure longer operational life and optimized production efficiency.

| ZT715(%) | ||||||

| C | Cr | Fe | W | Si | B | Ni |

| 0.6-0.9 | 11-13 | <5 | 8-15 | 1.2-2.0 | 0.8-1.2 | Bal. |

| ZT725(%) | ||||||

| C | Cr | Fe | W | Si | B | Ni |

| 0.8-1.5 | 9-11 | <5 | 19-25 | 2.5-3.5 | 0.8-1.2 | Bal. |

| ZT735(%) | ||||||

| C | W | Cu | Si | B | Ni | Others |

| 1.0-1.7 | 28-35 | 10-13 | 1.0-2.0 | 0.3-1.0 | Bal. | <2 |

ZHITIAN utilizes nickel-based tungsten carbide alloys (ZT715, ZT725, ZT735) to create a dense, fusion-bonded protective layer inside the barrel.

This laser cladding process forms a strong metallurgical bond with the base alloy steel, offering superior adhesion and eliminating surface defects such as cracks or porosity.

Key Benefits of ZHITIAN Laser Cladding Barrels:

High bonding strength and uniform coating thickness

Excellent wear and corrosion resistance

Reduced maintenance and longer replacement cycles

Stable performance under high torque and temperature conditions

Each twin screw extruder barrel consists of two key layers:

Base Layer: High-strength alloy steel that provides load-bearing capability and thermal stability.

Cladding Layer: A precision laser-cladded nickel-tungsten coating ensuring maximum surface protection and process consistency.

Combined with CNC boring, honing, and alignment machining, every ZHITIAN barrel achieves tight dimensional tolerances, excellent roundness, and improved extrusion flow.

ZHITIAN offers three material grades for different extrusion needs:

Grade | Description | Application |

ZT715 | Standard nickel-tungsten alloy | General plastic compounding |

ZT725 | Enhanced wear and corrosion protection | High filler plastics and engineering resins |

ZT735 | Maximum wear resistance | Abrasive materials, fiber-reinforced and composite extrusion |

Advantages:

Over 10× lifespan compared to nitrided barrels

Outstanding performance in glass-fiber, filler, and composite extrusion

Suitable for continuous high-load production

The Laser Cladding Screw Barrels are designed for a wide range of extrusion applications:

Engineering plastics such as PA, PC, PET, and PBT

Wood-plastic composites (WPC) and filler-rich materials

Degradable and bio-based polymers

Chemical and reactive extrusion

Battery material compounding in lithium or solid-state processes

Applicable for co-rotating twin screw extruders including models equivalent to ZSK, STS, TEX, CTE, and TDS series, with screw diameters of 65 mm and above.

ZHITIAN provides OEM-compatible and customized screw barrels tailored to global extrusion brands.

Customers can choose standard, feeding, venting, or side-feeder configurations, or request custom geometry for improved mixing and wear performance.

All barrels are manufactured under ISO 9001 quality control and 6S production management, ensuring repeatable precision and traceability.

Parameter | Description |

Technology | Laser cladding (Nickel-Tungsten Alloy) |

Material Options | ZT715 / ZT725 / ZT735 |

Base Alloy | High-strength alloy steel |

Suitable Extruder Diameter | Φ65 mm and above |

Manufacturing Process | CNC precision machining + laser cladding |

Application | Plastic, chemical, and composite extrusion |

Replacement Type | OEM & custom design available |

Brand | ZHITIAN |

Over 20 years of experience in extrusion component manufacturing

Proprietary alloy technology and advanced powder metallurgy expertise

Strong R&D capability and strict metrology-based inspection systems

Global export experience in Europe, America, and Southeast Asia

Q1: What makes ZHITIAN's laser cladding different from traditional coatings?

A1: It forms a metallurgical bond with the base metal, providing better coating strength, uniformity, and service life than thermal spray or nitrided barrels.

Q2: What extruder size is suitable for this barrel?

A2: ZHITIAN laser cladding barrels are ideal for Φ65 mm twin screw extruders and larger models.

Q3: Can the barrels be customized for specific materials?

A3: Yes. ZHITIAN provides customized cladding ratios and geometry according to polymer type, filler content, and process requirements.

Q4: How does laser cladding improve extrusion performance?

A4: The dense, high-hardness surface layer significantly reduces wear, maintains pressure stability, and minimizes material contamination over long production cycles.

The ZHITIAN Laser Cladding Nickel-Based Tungsten Carbide Screw Barrel is engineered for twin screw extruders with diameters of 65 mm and above, delivering exceptional wear resistance, corrosion protection, and dimensional stability. Using advanced laser cladding technology, ZHITIAN provides extrusion barrels that ensure longer operational life and optimized production efficiency.

| ZT715(%) | ||||||

| C | Cr | Fe | W | Si | B | Ni |

| 0.6-0.9 | 11-13 | <5 | 8-15 | 1.2-2.0 | 0.8-1.2 | Bal. |

| ZT725(%) | ||||||

| C | Cr | Fe | W | Si | B | Ni |

| 0.8-1.5 | 9-11 | <5 | 19-25 | 2.5-3.5 | 0.8-1.2 | Bal. |

| ZT735(%) | ||||||

| C | W | Cu | Si | B | Ni | Others |

| 1.0-1.7 | 28-35 | 10-13 | 1.0-2.0 | 0.3-1.0 | Bal. | <2 |

ZHITIAN utilizes nickel-based tungsten carbide alloys (ZT715, ZT725, ZT735) to create a dense, fusion-bonded protective layer inside the barrel.

This laser cladding process forms a strong metallurgical bond with the base alloy steel, offering superior adhesion and eliminating surface defects such as cracks or porosity.

Key Benefits of ZHITIAN Laser Cladding Barrels:

High bonding strength and uniform coating thickness

Excellent wear and corrosion resistance

Reduced maintenance and longer replacement cycles

Stable performance under high torque and temperature conditions

Each twin screw extruder barrel consists of two key layers:

Base Layer: High-strength alloy steel that provides load-bearing capability and thermal stability.

Cladding Layer: A precision laser-cladded nickel-tungsten coating ensuring maximum surface protection and process consistency.

Combined with CNC boring, honing, and alignment machining, every ZHITIAN barrel achieves tight dimensional tolerances, excellent roundness, and improved extrusion flow.

ZHITIAN offers three material grades for different extrusion needs:

Grade | Description | Application |

ZT715 | Standard nickel-tungsten alloy | General plastic compounding |

ZT725 | Enhanced wear and corrosion protection | High filler plastics and engineering resins |

ZT735 | Maximum wear resistance | Abrasive materials, fiber-reinforced and composite extrusion |

Advantages:

Over 10× lifespan compared to nitrided barrels

Outstanding performance in glass-fiber, filler, and composite extrusion

Suitable for continuous high-load production

The Laser Cladding Screw Barrels are designed for a wide range of extrusion applications:

Engineering plastics such as PA, PC, PET, and PBT

Wood-plastic composites (WPC) and filler-rich materials

Degradable and bio-based polymers

Chemical and reactive extrusion

Battery material compounding in lithium or solid-state processes

Applicable for co-rotating twin screw extruders including models equivalent to ZSK, STS, TEX, CTE, and TDS series, with screw diameters of 65 mm and above.

ZHITIAN provides OEM-compatible and customized screw barrels tailored to global extrusion brands.

Customers can choose standard, feeding, venting, or side-feeder configurations, or request custom geometry for improved mixing and wear performance.

All barrels are manufactured under ISO 9001 quality control and 6S production management, ensuring repeatable precision and traceability.

Parameter | Description |

Technology | Laser cladding (Nickel-Tungsten Alloy) |

Material Options | ZT715 / ZT725 / ZT735 |

Base Alloy | High-strength alloy steel |

Suitable Extruder Diameter | Φ65 mm and above |

Manufacturing Process | CNC precision machining + laser cladding |

Application | Plastic, chemical, and composite extrusion |

Replacement Type | OEM & custom design available |

Brand | ZHITIAN |

Over 20 years of experience in extrusion component manufacturing

Proprietary alloy technology and advanced powder metallurgy expertise

Strong R&D capability and strict metrology-based inspection systems

Global export experience in Europe, America, and Southeast Asia

Q1: What makes ZHITIAN's laser cladding different from traditional coatings?

A1: It forms a metallurgical bond with the base metal, providing better coating strength, uniformity, and service life than thermal spray or nitrided barrels.

Q2: What extruder size is suitable for this barrel?

A2: ZHITIAN laser cladding barrels are ideal for Φ65 mm twin screw extruders and larger models.

Q3: Can the barrels be customized for specific materials?

A3: Yes. ZHITIAN provides customized cladding ratios and geometry according to polymer type, filler content, and process requirements.

Q4: How does laser cladding improve extrusion performance?

A4: The dense, high-hardness surface layer significantly reduces wear, maintains pressure stability, and minimizes material contamination over long production cycles.