English

| Availability: | |

|---|---|

| Quantity: | |

zhitian

TWIN-SCREW SLURRY MIXING BARREL

Twin-screw extruder pulping is an innovative technology in the lithium battery industry, which can realize continuous production of battery slurry and improve the production efficiency and quality of lithium batteries. However, the particularity of the battery slurry puts forward higher standards for the twin-screw extruder, which not only require wear resistance and corrosion resistance, but also be customized according to the different characteristics of the positive and negative electrodes of the battery.

EXPLORER OF NEW MATERIAL TECHNOLOGY

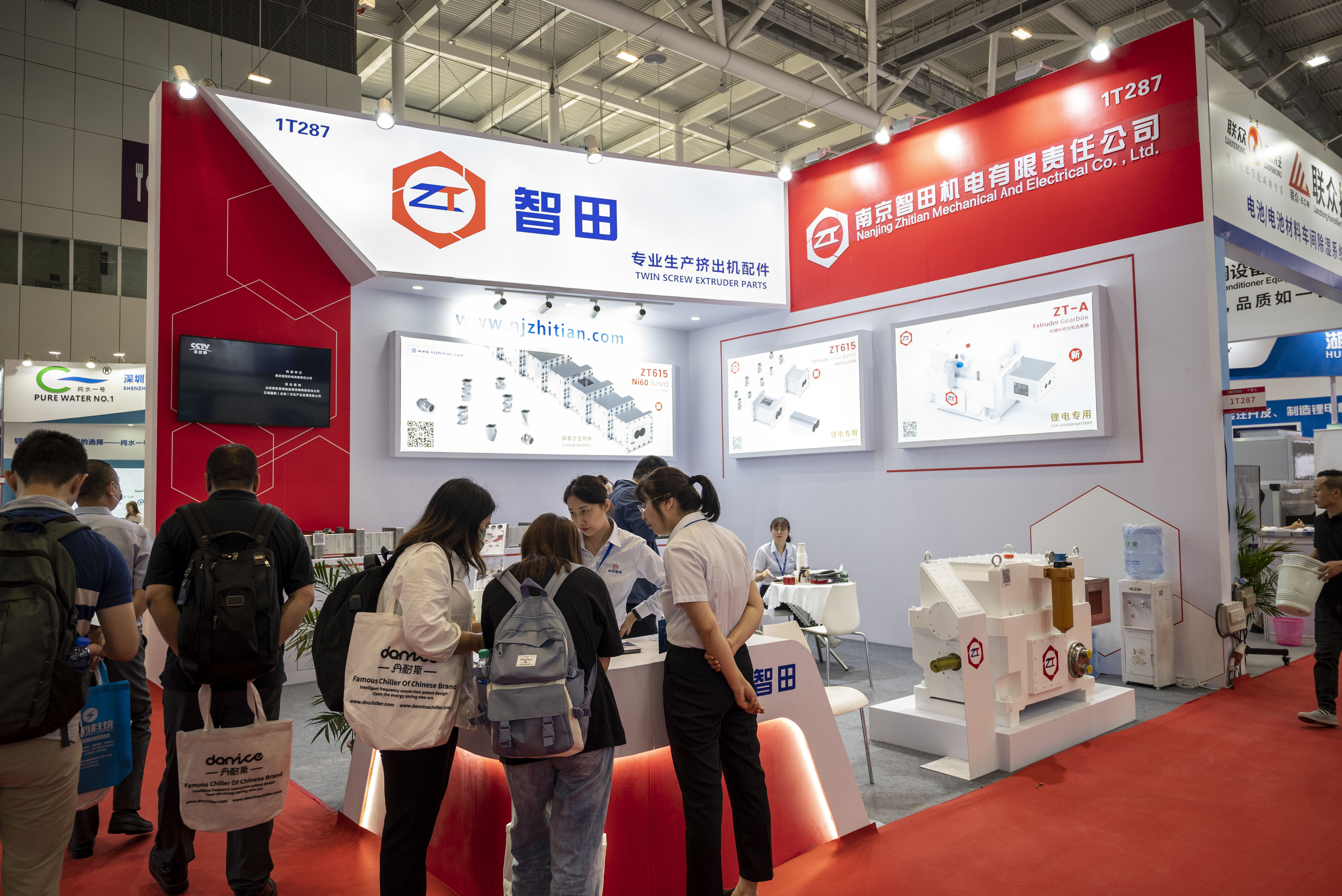

Nanjing Zhitian Electromechanical Co., Ltd. is a leading manufacturer and researcher of extruder accessories in China, as well as an explorer of new material technology. Since its establishment in 2006, relying on nearly 20 years of technology accumulation and innovation capabilities, the company has provided high-quality products and services for many fields such as plastic chemical industry, food processing, powder coating, military technology and battery homogenate.

![]()

TAILOR-MADE PRECISION

We specialize in designing and manufacturing screw elements, barrels and gearboxes that precisely meet customer requirements. By understanding our customers' needs, we create custom solutions that optimize efficiency and productivity, ensuring stability in extrusion systems.

DECADES OF EXPERTISE

With more than twenty years of experience in this field, we have become a trusted partner of world-renowned companies. Our track record speaks volumes for the quality and reliability of our products, making us the choice of customers seeking excellence in the extrusion industry.

ADVANCING MATERIALS TECHNOLOGY

Our commitment to innovation pushes us to push the boundaries of material technology. Our hot press sintering technology enables us to produce nickel based solid alloy sleeves with outstanding precision and durability. Additionally, we can compound alloys directly onto the inner wall of the screw barrel, providing a tailored solution that excels in challenging extrusion applications.

With our strong design capability, rich industry experience and advanced material technology. Trust us to deliver outstanding performance and consistent quality in every twin screw extruder component we manufacture. Choose us as your partner in the twin screw industry and experience the difference our expertise, experience and advanced technology make. Together we can unlock new possibilities and drive your success to even greater heights.

TWIN-SCREW SLURRY MIXING BARREL

Twin-screw extruder pulping is an innovative technology in the lithium battery industry, which can realize continuous production of battery slurry and improve the production efficiency and quality of lithium batteries. However, the particularity of the battery slurry puts forward higher standards for the twin-screw extruder, which not only require wear resistance and corrosion resistance, but also be customized according to the different characteristics of the positive and negative electrodes of the battery.

EXPLORER OF NEW MATERIAL TECHNOLOGY

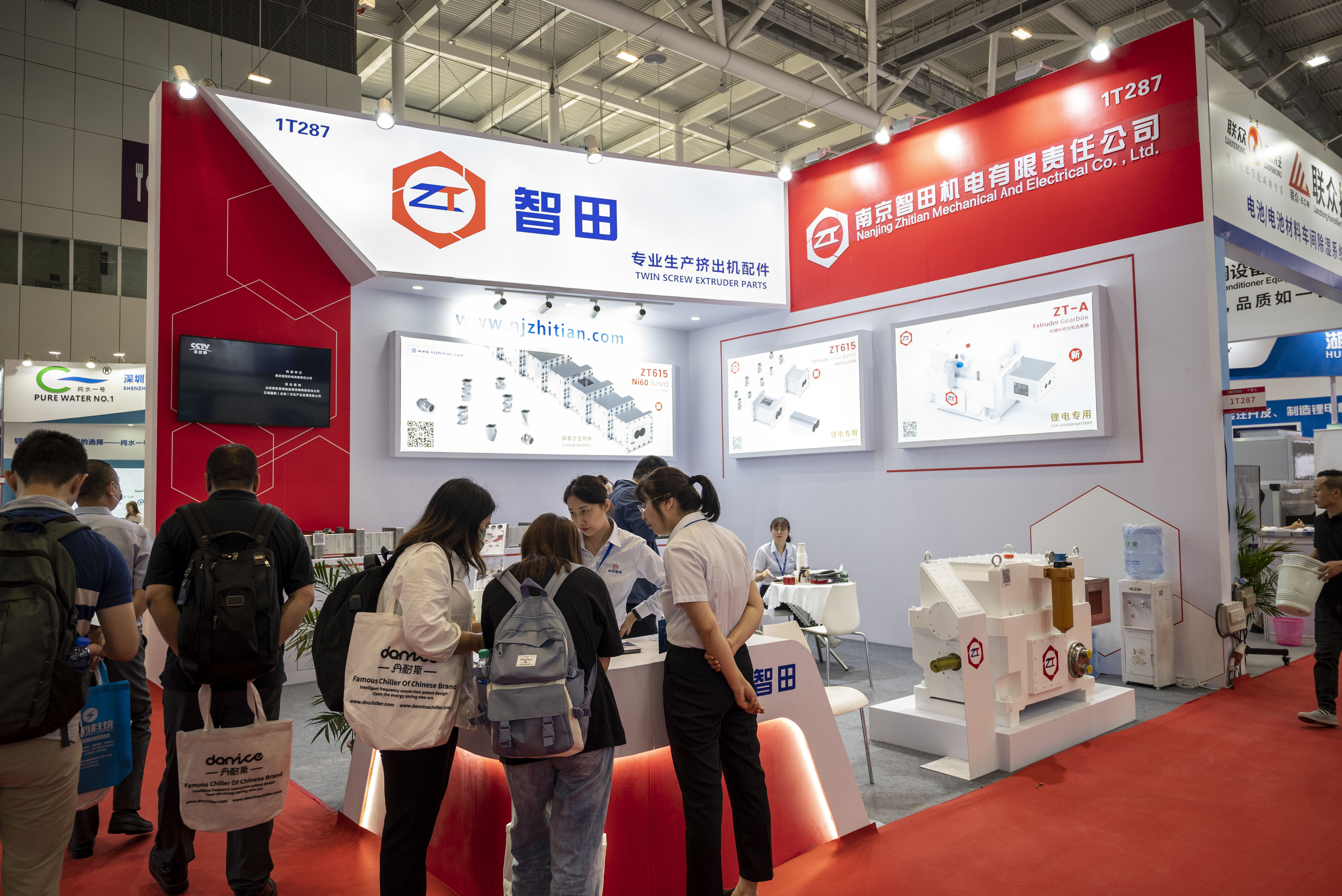

Nanjing Zhitian Electromechanical Co., Ltd. is a leading manufacturer and researcher of extruder accessories in China, as well as an explorer of new material technology. Since its establishment in 2006, relying on nearly 20 years of technology accumulation and innovation capabilities, the company has provided high-quality products and services for many fields such as plastic chemical industry, food processing, powder coating, military technology and battery homogenate.

![]()

TAILOR-MADE PRECISION

We specialize in designing and manufacturing screw elements, barrels and gearboxes that precisely meet customer requirements. By understanding our customers' needs, we create custom solutions that optimize efficiency and productivity, ensuring stability in extrusion systems.

DECADES OF EXPERTISE

With more than twenty years of experience in this field, we have become a trusted partner of world-renowned companies. Our track record speaks volumes for the quality and reliability of our products, making us the choice of customers seeking excellence in the extrusion industry.

ADVANCING MATERIALS TECHNOLOGY

Our commitment to innovation pushes us to push the boundaries of material technology. Our hot press sintering technology enables us to produce nickel based solid alloy sleeves with outstanding precision and durability. Additionally, we can compound alloys directly onto the inner wall of the screw barrel, providing a tailored solution that excels in challenging extrusion applications.

With our strong design capability, rich industry experience and advanced material technology. Trust us to deliver outstanding performance and consistent quality in every twin screw extruder component we manufacture. Choose us as your partner in the twin screw industry and experience the difference our expertise, experience and advanced technology make. Together we can unlock new possibilities and drive your success to even greater heights.