English

| Availability: | |

|---|---|

| Quantity: | |

Customization

zhitian

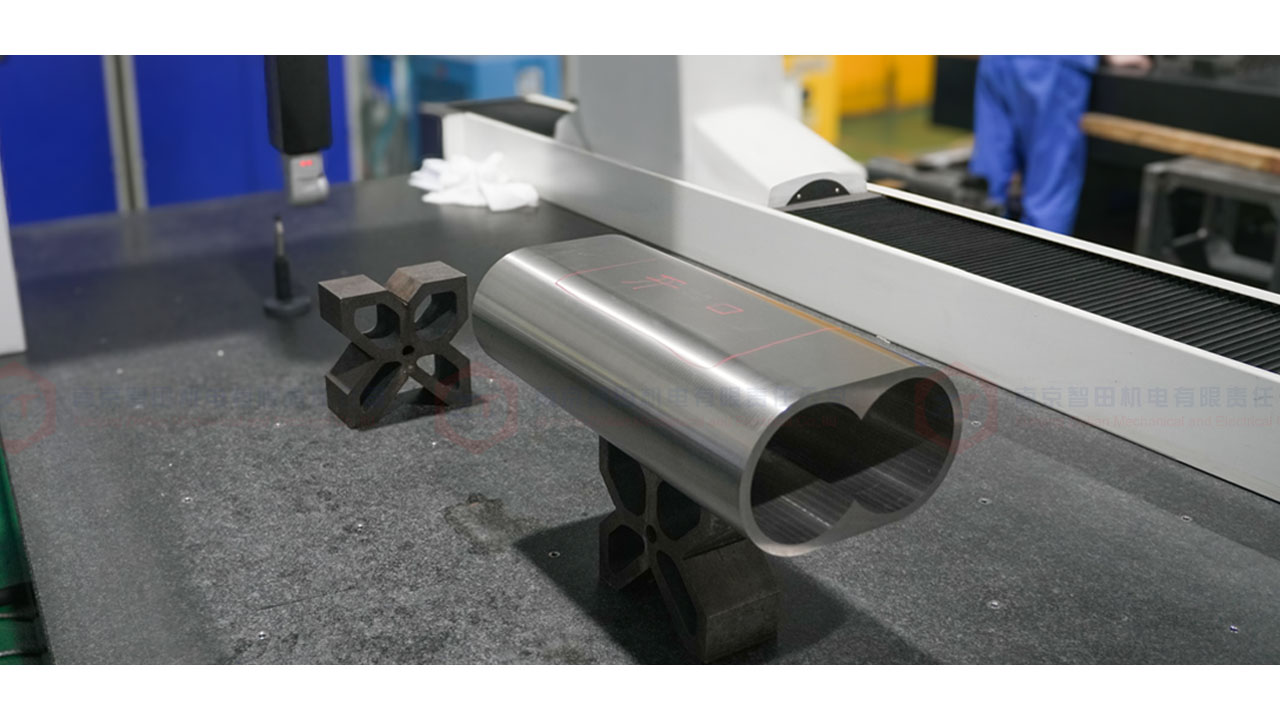

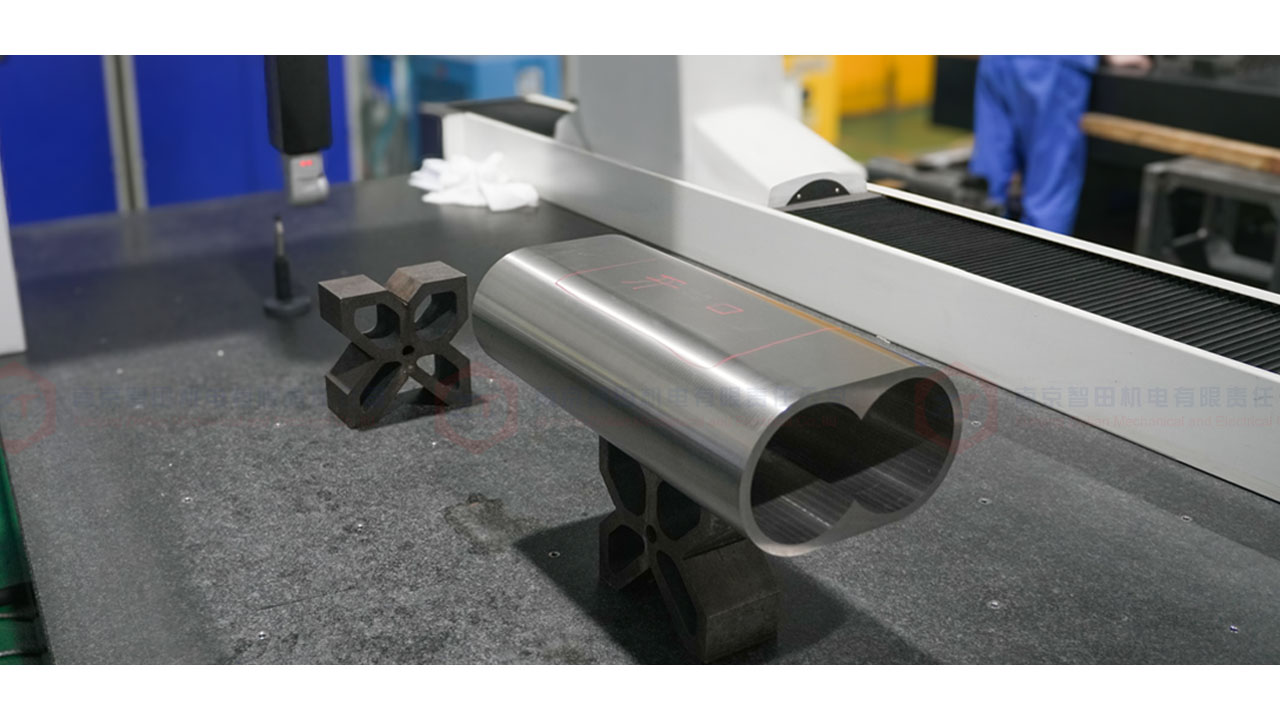

ZT818 is a tungsten-cobalt hard alloy independently developed by ZHITIAN for twin screw extruder barrels.

It combines 82% tungsten carbide (WC) and 18% cobalt (Co) through cold isostatic pressing (CIP) and precision sintering.

This alloy delivers ultra-high hardness HRA>83(HRC 68–69), impact toughness >13 J/cm², and exceptional wear resistance, setting the industrial benchmark for high-load extrusion components.

ZT818 stands as the pinnacle of wear-resistant materials, often referred to as the 'ceiling of metal-ceramic performance.'

Compared with traditional tool steel or cermet composites, it offers:

Over 20× higher wear resistance than high-speed steel (6542)

Excellent mechanical toughness for long-term extrusion operation

Superior density and bonding strength from ZHITIAN’s advanced powder metallurgy process

Outstanding thermal stability, maintaining hardness under high extrusion temperatures

These properties make ZT818 ideal for twin screw extruder barrel sleeves that require both extreme wear protection and dimensional precision.

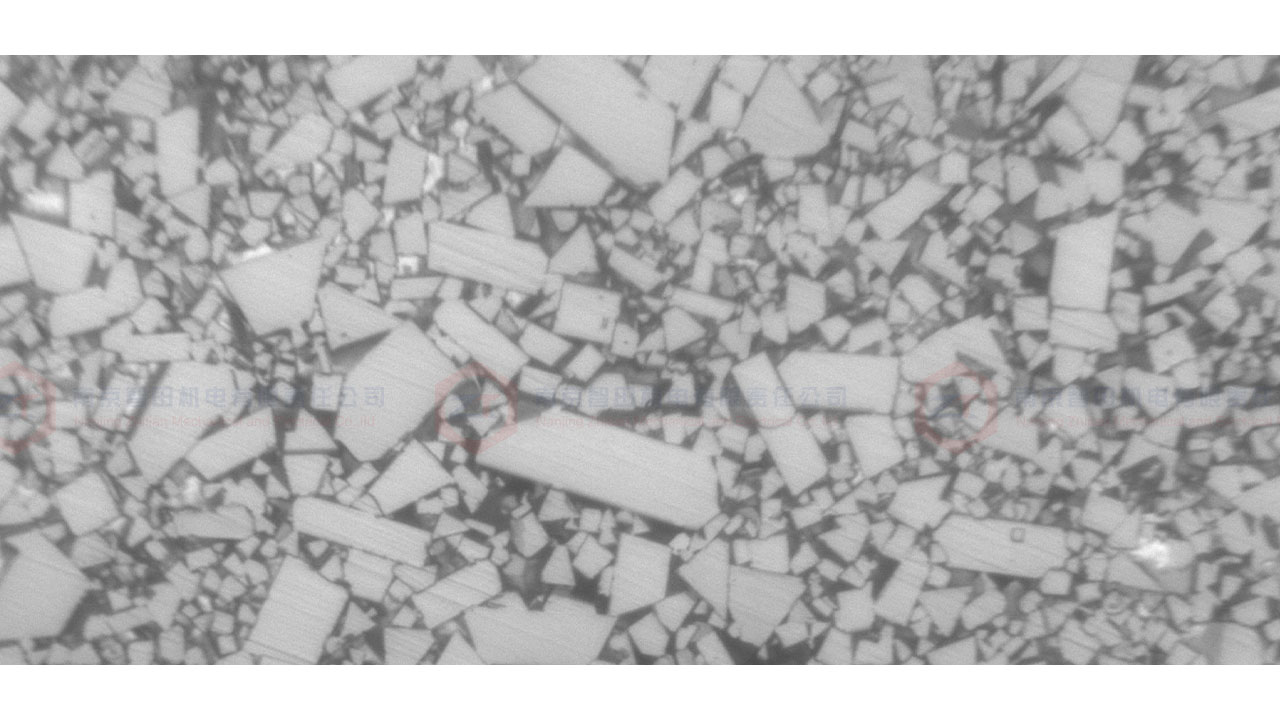

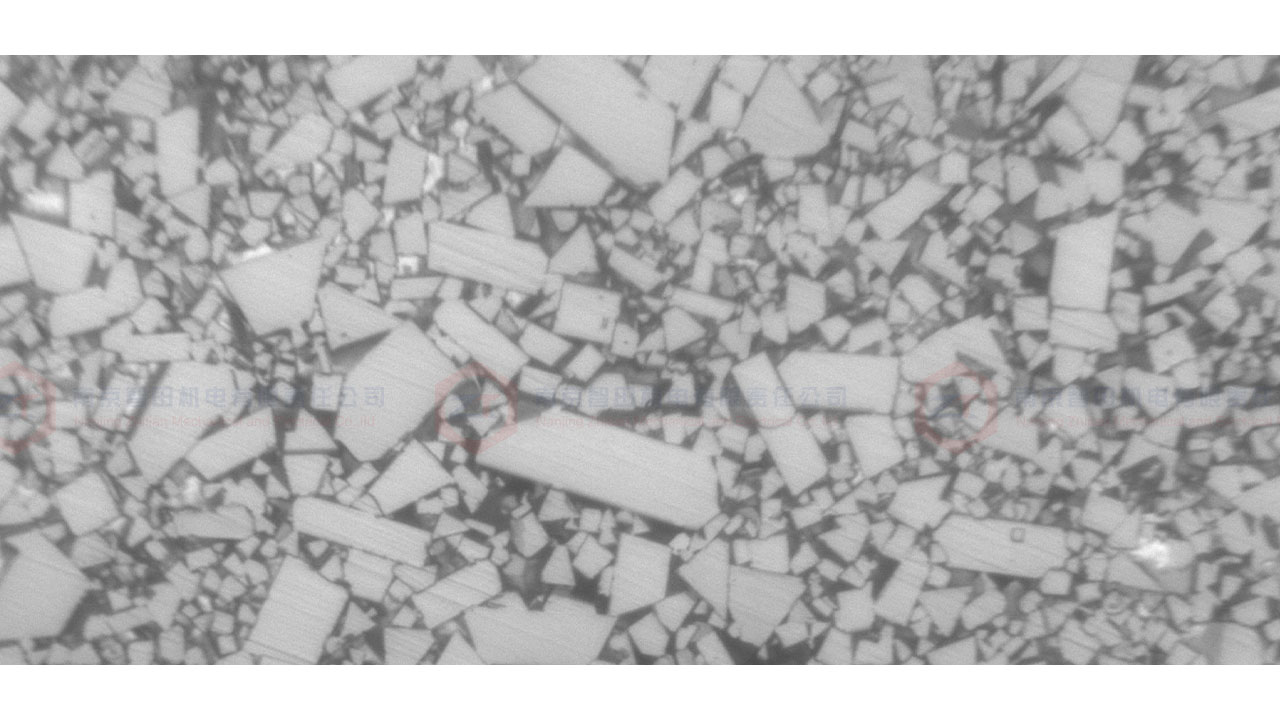

ZHITIAN applies a cold isostatic pressing and sintering process to achieve a dense and uniform microstructure in ZT818 alloy:

Powder Blending – 82% tungsten carbide mixed with 18% cobalt binder

CIP Molding – Uniform compression to eliminate internal porosity

Precision Sintering – Controlled atmosphere and temperature for full metallurgical bonding

Final Machining – CNC finishing ensures high dimensional accuracy for twin screw extruder barrel installation

This process guarantees both high mechanical strength and long-lasting surface stability under extreme wear conditions.

ZT818 is widely used in wear-critical extruder components, especially barrel sleeves for:

Engineering plastics and glass-fiber compounds

Wood-plastic composites (WPC)

Masterbatch and filler compounding

Flame-retardant and mineral-filled polymers

Lithium battery electrode slurry production

In these sectors, ZT818 enables longer service life, stable extrusion quality, and reduced maintenance downtime.

| Property | Unit | ZT818 Alloy |

Composition | – | 82% WC + 18% Co |

Hardness | HRC | 68–69 |

Impact Toughness | J/cm² | >13 |

Density | g/cm³ | ≈14.3 |

Process | – | Cold Isostatic Pressing + Sintering |

| Material | Initial Weight (g) | Final Weight (g) | Weight Loss (g) | Relative Wear Resistance |

High-Speed Steel 6542 | 63.5517 | 63.4817 | 0.0700 | 1× (baseline) |

ZT818 Alloy | 74.3217 | 74.3181 | 0.0036 | >20× |

Result:

ZT818's wear resistance is over 20 times greater than 6542, proving its unmatched durability for abrasive extrusion environments.

ZHITIAN's R&D team has achieved breakthroughs in powder metallurgy and hard alloy formulation, making ZT818 a flagship solution for the next generation of extrusion materials.

It outperforms traditional alloys in hardness, toughness, and thermal endurance, making it a top choice for customers seeking the longest-lasting extruder barrel solution.

Ultimate wear resistance under abrasive extrusion

Over 20× longer lifespan than standard tool steels

Maintains high precision and stability at elevated temperatures

Metallurgical bonding ensures structural integrity

Developed and produced by ZHITIAN, a leading manufacturer of twin screw extruder components

ZT818 is a tungsten-cobalt hard alloy independently developed by ZHITIAN for twin screw extruder barrels.

It combines 82% tungsten carbide (WC) and 18% cobalt (Co) through cold isostatic pressing (CIP) and precision sintering.

This alloy delivers ultra-high hardness HRA>83(HRC 68–69), impact toughness >13 J/cm², and exceptional wear resistance, setting the industrial benchmark for high-load extrusion components.

ZT818 stands as the pinnacle of wear-resistant materials, often referred to as the 'ceiling of metal-ceramic performance.'

Compared with traditional tool steel or cermet composites, it offers:

Over 20× higher wear resistance than high-speed steel (6542)

Excellent mechanical toughness for long-term extrusion operation

Superior density and bonding strength from ZHITIAN’s advanced powder metallurgy process

Outstanding thermal stability, maintaining hardness under high extrusion temperatures

These properties make ZT818 ideal for twin screw extruder barrel sleeves that require both extreme wear protection and dimensional precision.

ZHITIAN applies a cold isostatic pressing and sintering process to achieve a dense and uniform microstructure in ZT818 alloy:

Powder Blending – 82% tungsten carbide mixed with 18% cobalt binder

CIP Molding – Uniform compression to eliminate internal porosity

Precision Sintering – Controlled atmosphere and temperature for full metallurgical bonding

Final Machining – CNC finishing ensures high dimensional accuracy for twin screw extruder barrel installation

This process guarantees both high mechanical strength and long-lasting surface stability under extreme wear conditions.

ZT818 is widely used in wear-critical extruder components, especially barrel sleeves for:

Engineering plastics and glass-fiber compounds

Wood-plastic composites (WPC)

Masterbatch and filler compounding

Flame-retardant and mineral-filled polymers

Lithium battery electrode slurry production

In these sectors, ZT818 enables longer service life, stable extrusion quality, and reduced maintenance downtime.

| Property | Unit | ZT818 Alloy |

Composition | – | 82% WC + 18% Co |

Hardness | HRC | 68–69 |

Impact Toughness | J/cm² | >13 |

Density | g/cm³ | ≈14.3 |

Process | – | Cold Isostatic Pressing + Sintering |

| Material | Initial Weight (g) | Final Weight (g) | Weight Loss (g) | Relative Wear Resistance |

High-Speed Steel 6542 | 63.5517 | 63.4817 | 0.0700 | 1× (baseline) |

ZT818 Alloy | 74.3217 | 74.3181 | 0.0036 | >20× |

Result:

ZT818's wear resistance is over 20 times greater than 6542, proving its unmatched durability for abrasive extrusion environments.

ZHITIAN's R&D team has achieved breakthroughs in powder metallurgy and hard alloy formulation, making ZT818 a flagship solution for the next generation of extrusion materials.

It outperforms traditional alloys in hardness, toughness, and thermal endurance, making it a top choice for customers seeking the longest-lasting extruder barrel solution.

Ultimate wear resistance under abrasive extrusion

Over 20× longer lifespan than standard tool steels

Maintains high precision and stability at elevated temperatures

Metallurgical bonding ensures structural integrity

Developed and produced by ZHITIAN, a leading manufacturer of twin screw extruder components