English

| Availability: | |

|---|---|

| Quantity: | |

Customization

zhitian

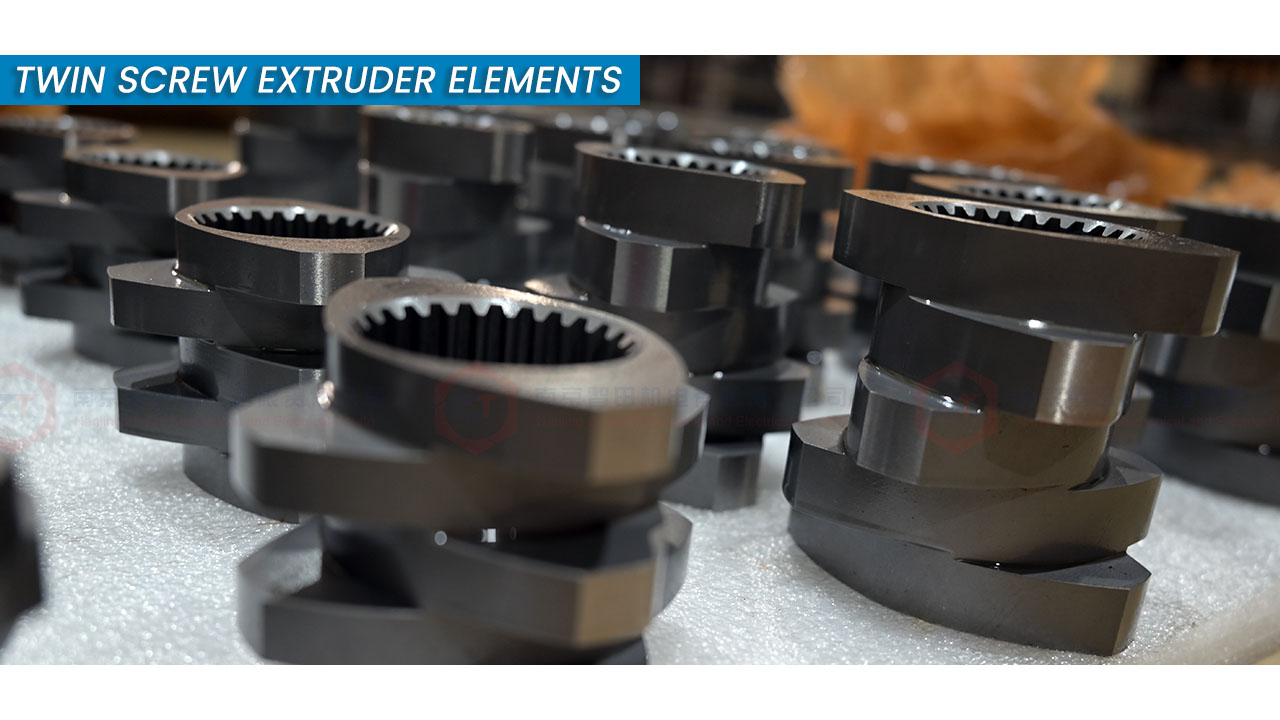

In twin screw extrusion, screw elements are not only conveying components but functional process tools. Different element geometries provide different roles in material transport and processing:

Right-hand conveying elements transport material forward

Left-hand elements generate reverse conveying and backflow

Neutral elements provide no conveying force and mainly affect residence time and filling behavior

Each element type influences filling ratio, residence time, and pressure distribution differently. Especially in kneading zones, material compression directly affects processing performance.

ZHITIAN designs screw element systems based on functional zoning rather than isolated elements, ensuring that each section of the screw performs a clear and controlled role.

| Item | Description |

|---|---|

| Element Types | Conveying, reverse conveying, neutral, kneading |

| Kneading Design | Adjustable disc thickness and disc number |

| Clearance Control | Optimized disc-to-barrel gap |

| Function Zones | Conveying, filling, mixing, shearing |

| Materials | Tool steel, PM-HIP alloys, corrosion-resistant alloys |

| Heat Treatment | Wear and fatigue optimized |

| Configuration | Modular and interchangeable |

| Customization | Available based on process requirements |

Forward, reverse, and neutral elements are combined to control material flow direction, filling degree, and pressure build-up.

Element geometry and combination regulate material residence time, avoiding under-processing or thermal degradation.

Shear intensity varies significantly with element design and arrangement. Optimized forming geometry ensures process stability and material integrity.

Kneading elements play a critical role in mixing efficiency. Parameters such as:

Disc thickness

Disc-to-barrel clearance (gap)

Number of kneading discs

directly influence dispersive and distributive mixing performance.

Only rational combination of different functional elements can achieve optimal processing performance, rather than relying on a single element type.

Functional screw elements are widely used in:

Polymer compounding and modification

Masterbatch production

Reactive extrusion

High-performance mixing processes

Chemical material processing

Food and feed extrusion

They are suitable for both development lines and industrial continuous production systems.

Selection should be based on required conveying behavior, shear intensity, and residence time rather than machine size alone.

Right-hand elements convey material forward, while left-hand elements generate reverse flow and pressure build-up.

Parameters such as disc thickness, clearance, and disc number directly determine dispersive and homogenizing mixing performance.

Yes. Functional design allows precise control of flow, shear, and mixing, ensuring stable product quality.

ZHITIAN specializes in the development and manufacturing of twin screw extruder components, including screw elements, barrels, and gearboxes. Through long-term application experience and functional configuration design, ZHITIAN provides reliable and efficient processing solutions for complex extrusion systems.

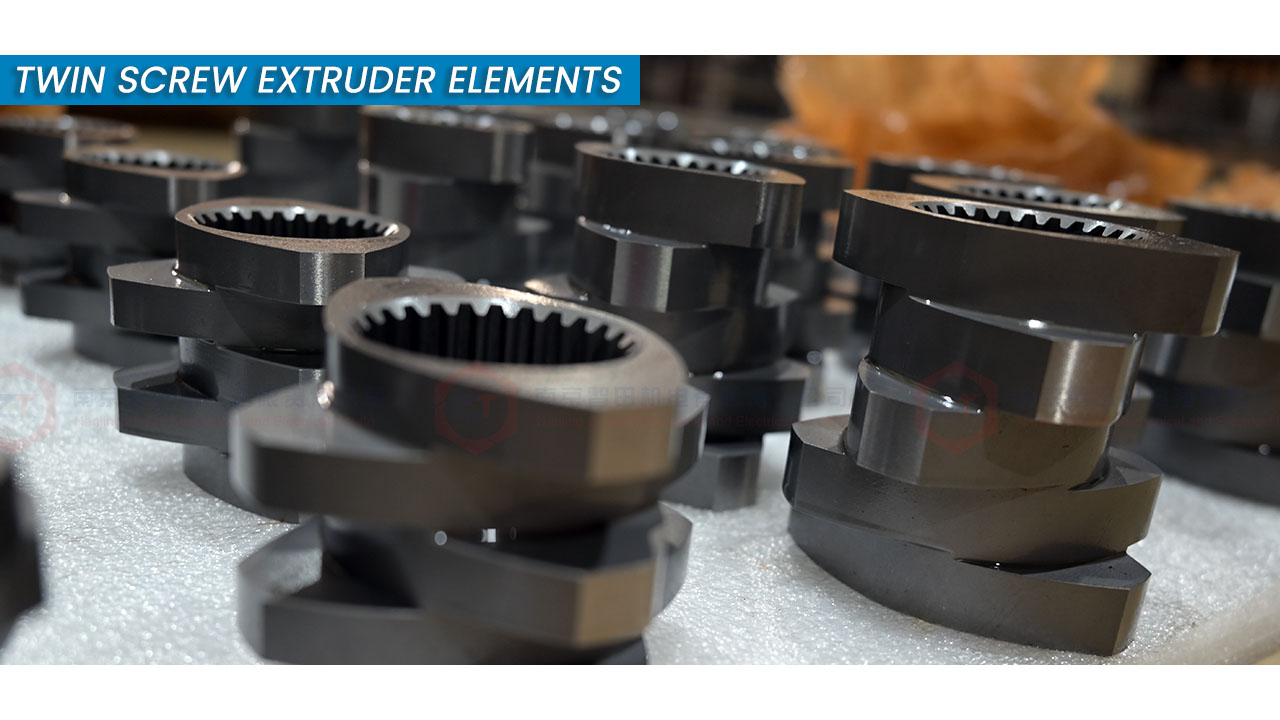

In twin screw extrusion, screw elements are not only conveying components but functional process tools. Different element geometries provide different roles in material transport and processing:

Right-hand conveying elements transport material forward

Left-hand elements generate reverse conveying and backflow

Neutral elements provide no conveying force and mainly affect residence time and filling behavior

Each element type influences filling ratio, residence time, and pressure distribution differently. Especially in kneading zones, material compression directly affects processing performance.

ZHITIAN designs screw element systems based on functional zoning rather than isolated elements, ensuring that each section of the screw performs a clear and controlled role.

| Item | Description |

|---|---|

| Element Types | Conveying, reverse conveying, neutral, kneading |

| Kneading Design | Adjustable disc thickness and disc number |

| Clearance Control | Optimized disc-to-barrel gap |

| Function Zones | Conveying, filling, mixing, shearing |

| Materials | Tool steel, PM-HIP alloys, corrosion-resistant alloys |

| Heat Treatment | Wear and fatigue optimized |

| Configuration | Modular and interchangeable |

| Customization | Available based on process requirements |

Forward, reverse, and neutral elements are combined to control material flow direction, filling degree, and pressure build-up.

Element geometry and combination regulate material residence time, avoiding under-processing or thermal degradation.

Shear intensity varies significantly with element design and arrangement. Optimized forming geometry ensures process stability and material integrity.

Kneading elements play a critical role in mixing efficiency. Parameters such as:

Disc thickness

Disc-to-barrel clearance (gap)

Number of kneading discs

directly influence dispersive and distributive mixing performance.

Only rational combination of different functional elements can achieve optimal processing performance, rather than relying on a single element type.

Functional screw elements are widely used in:

Polymer compounding and modification

Masterbatch production

Reactive extrusion

High-performance mixing processes

Chemical material processing

Food and feed extrusion

They are suitable for both development lines and industrial continuous production systems.

Selection should be based on required conveying behavior, shear intensity, and residence time rather than machine size alone.

Right-hand elements convey material forward, while left-hand elements generate reverse flow and pressure build-up.

Parameters such as disc thickness, clearance, and disc number directly determine dispersive and homogenizing mixing performance.

Yes. Functional design allows precise control of flow, shear, and mixing, ensuring stable product quality.

ZHITIAN specializes in the development and manufacturing of twin screw extruder components, including screw elements, barrels, and gearboxes. Through long-term application experience and functional configuration design, ZHITIAN provides reliable and efficient processing solutions for complex extrusion systems.