English

| Availability: | |

|---|---|

| Quantity: | |

Customization

zhitian

Unlike general plastic compounding, masterbatch extrusion typically involves high pigment or filler loadings, which significantly affect melt viscosity and flow behavior. Insufficient dispersion can lead to color streaking, agglomerates, and unstable product quality.

Screw element design directly determines:

Pigment and filler dispersion quality

Shear distribution along the screw

Thermal stability of color systems

Consistency between production batches

Therefore, screw configurations for masterbatch production must be carefully engineered rather than adapted from standard plastic extrusion designs.

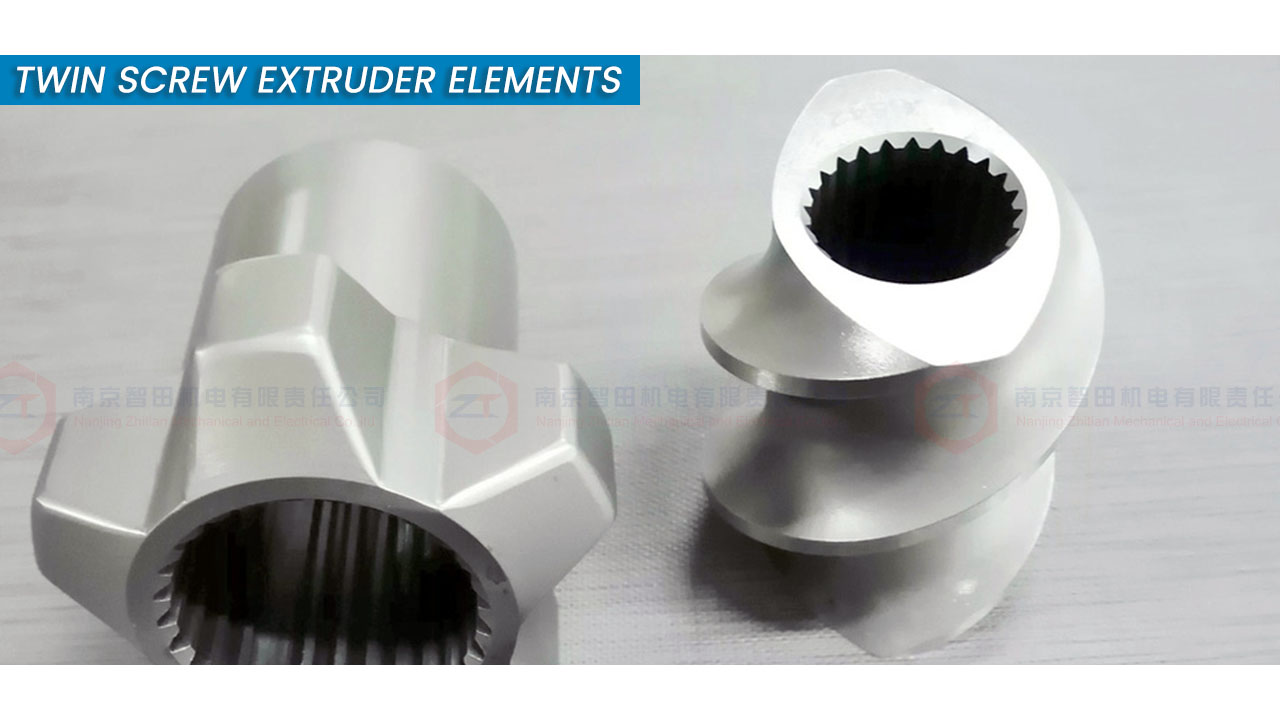

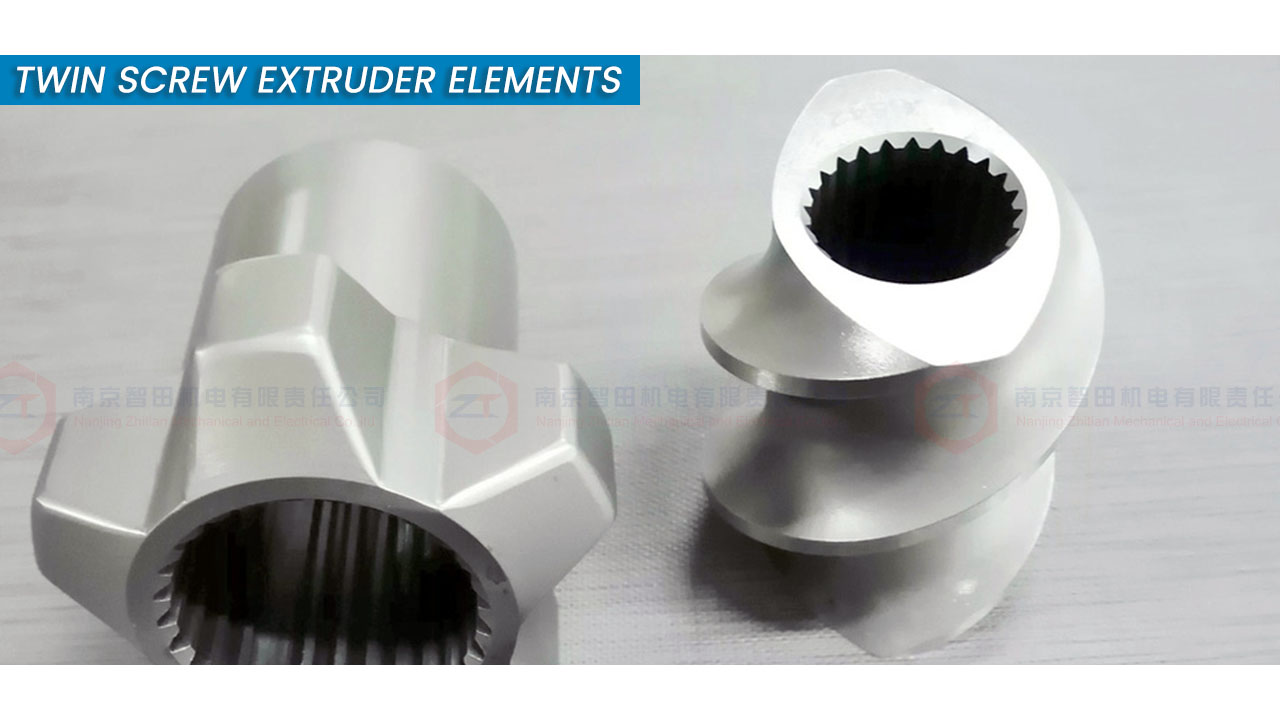

Masterbatch-focused screw profiles are built using modular screw elements assembled along the shaft, including:

Conveying elements for stable feeding and transport

Specialized kneading elements for intensive dispersive mixing

Functional elements to manage pressure buildup and residence time

By controlling the number, angle, and sequence of kneading elements, dispersion efficiency can be maximized while avoiding excessive shear that may degrade pigments or carriers.

ZHITIAN designs masterbatch screw configurations based on real processing conditions, focusing on repeatability and long-term production stability rather than short-term output alone.

These screw elements are widely used in:

Color masterbatch production

Filler masterbatch (CaCO₃, talc, carbon black)

Additive masterbatch extrusion

High-concentration functional masterbatch systems

They are suitable for both pilot extrusion lines and continuous high-output masterbatch production.

High dispersion efficiency: Improved pigment and filler distribution

Stable color consistency: Reduced batch-to-batch variation

Shear control: Balanced mixing without pigment degradation

Process adaptability: Suitable for various carrier resins

Reliable performance: Consistent output under high loading conditions

They are designed to handle higher filler and pigment loadings with enhanced dispersion control.

Optimized kneading and residence control improve pigment breakup and uniform distribution.

Modular design allows adjustment for different pigment systems and carrier resins.

Yes. They are designed to manage high shear demands while maintaining process stability.

ZHITIAN specializes in twin screw extruder components for demanding applications such as masterbatch production. With extensive application experience and a focus on dispersion-driven design, ZHITIAN provides screw element solutions that support consistent color quality and reliable industrial production.

Unlike general plastic compounding, masterbatch extrusion typically involves high pigment or filler loadings, which significantly affect melt viscosity and flow behavior. Insufficient dispersion can lead to color streaking, agglomerates, and unstable product quality.

Screw element design directly determines:

Pigment and filler dispersion quality

Shear distribution along the screw

Thermal stability of color systems

Consistency between production batches

Therefore, screw configurations for masterbatch production must be carefully engineered rather than adapted from standard plastic extrusion designs.

Masterbatch-focused screw profiles are built using modular screw elements assembled along the shaft, including:

Conveying elements for stable feeding and transport

Specialized kneading elements for intensive dispersive mixing

Functional elements to manage pressure buildup and residence time

By controlling the number, angle, and sequence of kneading elements, dispersion efficiency can be maximized while avoiding excessive shear that may degrade pigments or carriers.

ZHITIAN designs masterbatch screw configurations based on real processing conditions, focusing on repeatability and long-term production stability rather than short-term output alone.

These screw elements are widely used in:

Color masterbatch production

Filler masterbatch (CaCO₃, talc, carbon black)

Additive masterbatch extrusion

High-concentration functional masterbatch systems

They are suitable for both pilot extrusion lines and continuous high-output masterbatch production.

High dispersion efficiency: Improved pigment and filler distribution

Stable color consistency: Reduced batch-to-batch variation

Shear control: Balanced mixing without pigment degradation

Process adaptability: Suitable for various carrier resins

Reliable performance: Consistent output under high loading conditions

They are designed to handle higher filler and pigment loadings with enhanced dispersion control.

Optimized kneading and residence control improve pigment breakup and uniform distribution.

Modular design allows adjustment for different pigment systems and carrier resins.

Yes. They are designed to manage high shear demands while maintaining process stability.

ZHITIAN specializes in twin screw extruder components for demanding applications such as masterbatch production. With extensive application experience and a focus on dispersion-driven design, ZHITIAN provides screw element solutions that support consistent color quality and reliable industrial production.