English

| Availability: | |

|---|---|

| Quantity: | |

Customization

zhitian

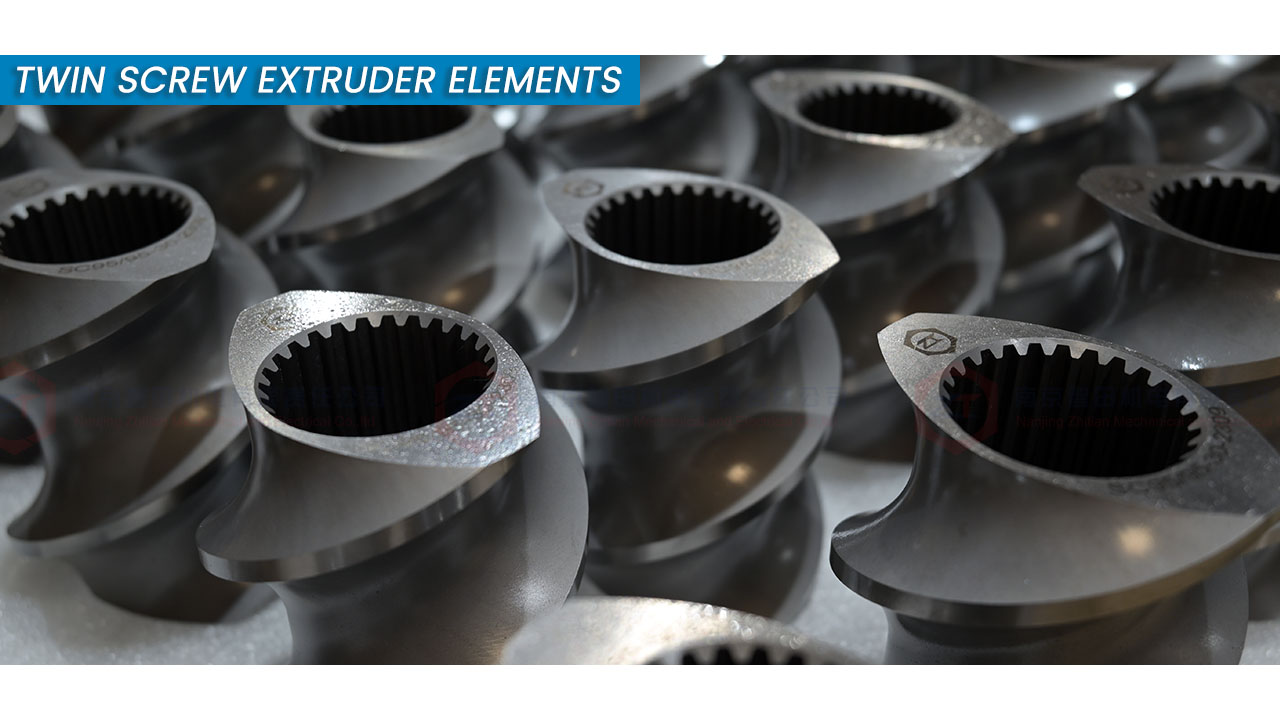

Modular twin screw extruder screw elements are individual functional components assembled axially on the screw shaft. Unlike one-piece screw designs, modular systems allow each element to perform a dedicated role within the extrusion process.

In a typical configuration:

Conveying elements are responsible for transporting material forward along the barrel.

Kneading elements focus on intensive mixing, dispersion, and homogenization of materials.

This modular design philosophy makes it possible to precisely control material flow, residence time, and mixing intensity throughout the extrusion process.

| Item | Description |

|---|---|

| Screw Type | Modular twin screw elements |

| Assembly Method | Axial assembly on screw shaft |

| Element Types | Conveying, kneading, functional elements |

| Materials | Tool steel, PM-HIP alloys, corrosion-resistant alloys |

| Heat Treatment | Wear-optimized and fatigue-resistant |

| Configuration | Customizable based on process |

| Compatibility | Mainstream twin screw extruder models |

| Manufacturer | ZHITIAN |

The key advantage of modular screw elements lies in their flexibility. By adjusting the type, number, and arrangement of screw elements, the screw structure can be customized for specific applications.

This allows engineers to:

Optimize processing for different raw materials

Adjust mixing intensity without changing the entire screw

Balance throughput, energy consumption, and product quality

ZHITIAN applies long-term extrusion experience and screw configuration know-how to design functional screw layouts that align with real processing requirements rather than theoretical parameters alone.

Modular twin screw screw elements are widely applied in:

Polymer compounding and modification

Masterbatch production

Chemical and reactive extrusion

Food and feed processing

Recycling and devolatilization processes

They are suitable for both R&D extrusion lines and large-scale industrial production.

Modular flexibility: Easy adjustment of screw configuration

Function-oriented design: Each element serves a clear processing purpose

Process optimization: Precise control of conveying and mixing

High compatibility: Suitable for mainstream twin screw extruders

Stable performance: Consistent product quality across applications

Selection depends on material properties, desired mixing level, and process goals rather than machine size alone.

Conveying elements transport material forward, while kneading elements provide intensive mixing and dispersion.

Yes. Modular design allows flexible adjustment of element types and sequences for specific applications.

They are suitable for plastics, chemicals, food, feed, and recycling industries.

ZHITIAN is a specialized manufacturer of twin screw extruder components, including screw elements, barrels, and gearboxes. With extensive application experience and a modular design approach, ZHITIAN provides reliable screw solutions tailored to complex extrusion processes.

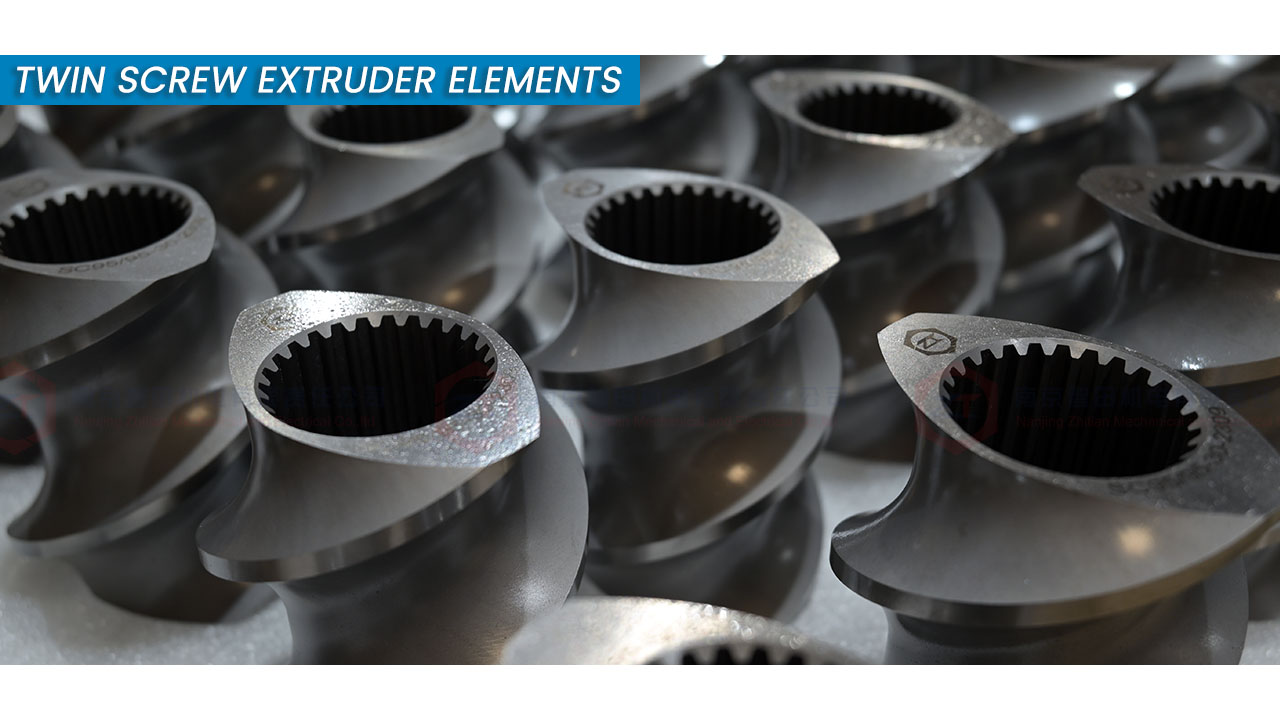

Modular twin screw extruder screw elements are individual functional components assembled axially on the screw shaft. Unlike one-piece screw designs, modular systems allow each element to perform a dedicated role within the extrusion process.

In a typical configuration:

Conveying elements are responsible for transporting material forward along the barrel.

Kneading elements focus on intensive mixing, dispersion, and homogenization of materials.

This modular design philosophy makes it possible to precisely control material flow, residence time, and mixing intensity throughout the extrusion process.

| Item | Description |

|---|---|

| Screw Type | Modular twin screw elements |

| Assembly Method | Axial assembly on screw shaft |

| Element Types | Conveying, kneading, functional elements |

| Materials | Tool steel, PM-HIP alloys, corrosion-resistant alloys |

| Heat Treatment | Wear-optimized and fatigue-resistant |

| Configuration | Customizable based on process |

| Compatibility | Mainstream twin screw extruder models |

| Manufacturer | ZHITIAN |

The key advantage of modular screw elements lies in their flexibility. By adjusting the type, number, and arrangement of screw elements, the screw structure can be customized for specific applications.

This allows engineers to:

Optimize processing for different raw materials

Adjust mixing intensity without changing the entire screw

Balance throughput, energy consumption, and product quality

ZHITIAN applies long-term extrusion experience and screw configuration know-how to design functional screw layouts that align with real processing requirements rather than theoretical parameters alone.

Modular twin screw screw elements are widely applied in:

Polymer compounding and modification

Masterbatch production

Chemical and reactive extrusion

Food and feed processing

Recycling and devolatilization processes

They are suitable for both R&D extrusion lines and large-scale industrial production.

Modular flexibility: Easy adjustment of screw configuration

Function-oriented design: Each element serves a clear processing purpose

Process optimization: Precise control of conveying and mixing

High compatibility: Suitable for mainstream twin screw extruders

Stable performance: Consistent product quality across applications

Selection depends on material properties, desired mixing level, and process goals rather than machine size alone.

Conveying elements transport material forward, while kneading elements provide intensive mixing and dispersion.

Yes. Modular design allows flexible adjustment of element types and sequences for specific applications.

They are suitable for plastics, chemicals, food, feed, and recycling industries.

ZHITIAN is a specialized manufacturer of twin screw extruder components, including screw elements, barrels, and gearboxes. With extensive application experience and a modular design approach, ZHITIAN provides reliable screw solutions tailored to complex extrusion processes.